ARUM INDUSTRIES

Engineering Precision in Every Thread

ARUM Industries is a globally focused manufacturer of advanced textile dyeing and finishing machinery, delivering efficient, reliable, and sustainable solutions for modern fabric processing.Driven by over three decades of engineering expertise and continuous innovation, ARUM designs machines that help textile manufacturers worldwide improve productivity, reduce resource consumption, and achieve consistent fabric quality across diverse applications.Our solutions support a wide range of processes, including high-volume tubular and open-width fabric dyeing, as well as post–bio-wash and finishing operations. Each system is engineered to meet the performance, quality, and environmental expectations of today’s global textile industry.Innovation in Soft Flow Dyeing TechnologyAs part of our commitment to future-ready textile solutions, ARUM introduces the Fluenta, HTHP Soft Flow Dyeing Machine developed with patent-pending technology. This next-generation system operates at an ultra-low liquor ratio of 1:2, significantly lower than conventional dyeing machines that typically require a ratio of 1:5.By reducing water usage, power consumption, and chemical requirements, the Fluenta Machine delivers measurable cost savings while maintaining excellent dye penetration, shade uniformity, and gentle fabric handling. Its energy-efficient design supports sustainability goals and compliance with international environmental standards.A Trusted Manufacturing PartnerEstablished in 1987, ARUM Industries brings over 38 years of experience in textile dyeing machinery manufacturing. Our equipment is trusted by manufacturers across major textile markets, with more than 1,000 installations worldwide.Today, ARUM Industries continues to expand its global presence, partnering with textile producers who seek reliable technology, long-term performance, and innovative solutions aligned with the future of sustainable textile processing.

© Arum Industries 2025. All rights reserved.

© Arum Industries 2025. All rights reserved.

bio fabric flush

In response to current industry challenges and with a strong commitment to worker welfare, we have developed the Bio Fabric Flush—a patent-pending innovation designed to remove fabric dust in water, preventing lint from mixing with air.

This ensures a cleaner work environment, safeguarding both productivity and worker health.Why Choose Bio Fabric Flush?

- Effective Dust Removal: Designed to eliminate fabric dust in wet processing for both tubular and non-tubular fabrics.

- Worker Safety: Creates a healthier work environment by preventing fabric lint from mixing with air.

- Reduced Air Pollution: Controls airborne particles, contributing to a cleaner factory atmosphere.

- Enhanced Productivity: Streamlined operations ensure higher efficiency in production.

- Optimized Power Consumption: Operates efficiently with just 7 HP power.

- Cost-Effective Solution: Offers advanced performance at an affordable investment.

© Arum Industries 2025. All rights reserved.

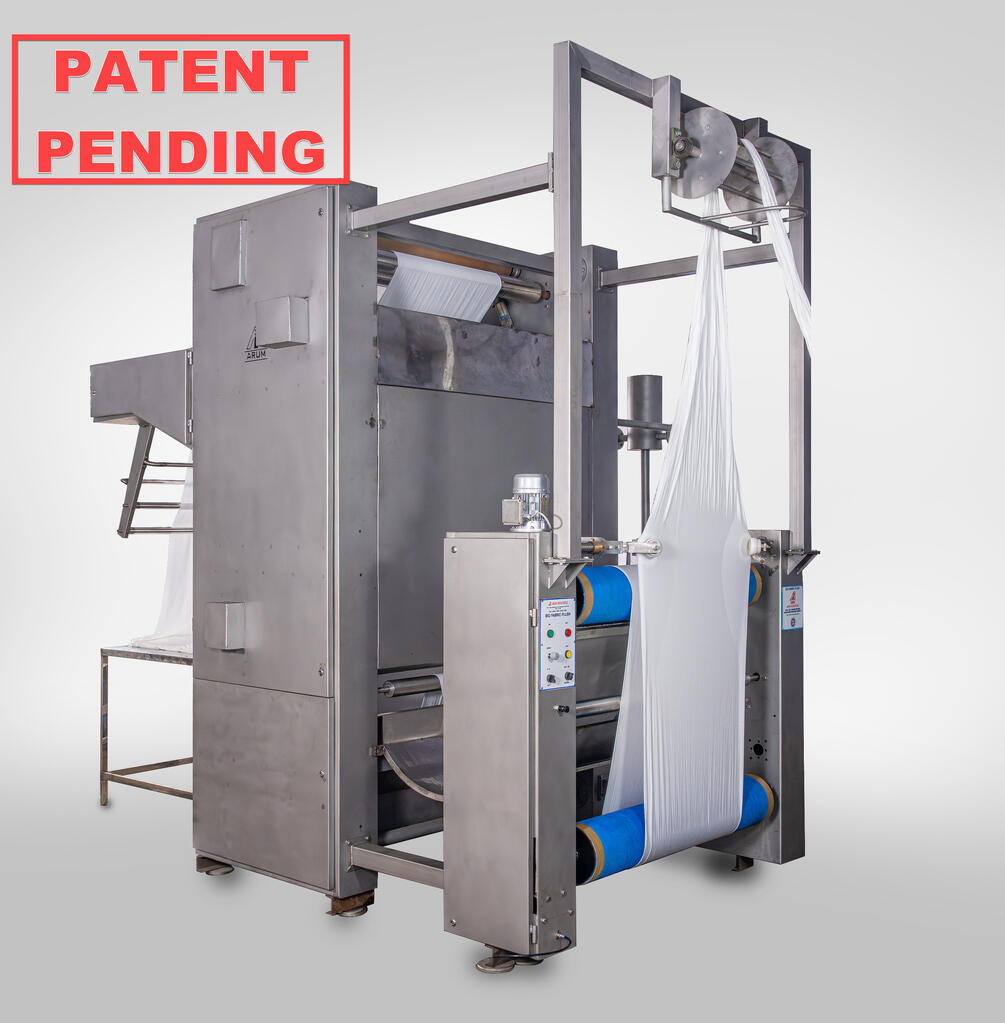

Balloon padding Squeezer

Our advanced Balloon Padding Squeezer for knitted fabrics is designed with innovative technology to optimize the preparation of wet tubular knitted fabrics, whether they come directly from the dyeing process or other damp treatments, before moving into the drying stage.Why Choose Balloon Padding Squeezer?

The machine enables continuous operation with superior efficiency, performing the following processes:De-twisting & Hydro Extraction – Achieves low residual moisture levels for faster drying.Tubular Height Adjustment – Automatic compensation and overfeeding folding directly onto the trolley.Balloon Hydro Extraction – Uses air injection from top to bottom for fabric extension and wrinkle-free results.Squeezing Cylinders – Ensures residual moisture levels below 75%, depending on fabric type.Simple Lever-Based Folding System – Enables smooth, crease-free fabric folding.Continuous Nonstop Feeding – Delivers high productivity while maintaining fabric quality without unwanted extension or distortion.Optimized Finishing Preparation – Creates ideal conditions for subsequent drying and finishing phases, reducing residual shrinkage in the final fabric.Specialized Advantages

- Prevents edge marks

- Eliminates crease marks

- High production capacity with consistent quality

© Arum Industries 2025. All rights reserved.

Fluenta - HTHP Softflow

The Fluenta is a new-generation HTHP Soft Flow Dyeing Machine designed to meet the evolving demands of modern textile dyeing. Developed with patent-pending technology, this machine delivers exceptional dyeing performance while dramatically reducing water, energy, and overall operating costs.Engineered for efficiency, sustainability, and fabric care, the Fluenta Machine enables manufacturers to achieve consistent, high-quality dyeing results with significantly lower resource consumption compared to traditional dyeing systems.Why Choose Fluenta Soft flow machine?Ultra-Low Liquor Ratio (1:2)

Advanced soft-flow technology reduces the water ratio to 1:2, compared to traditional machines operating at 1:5, resulting in substantial water savings.Reduced Power Consumption

Optimized flow dynamics and efficient system design lower electricity usage, directly reducing energy costs per batch.Lower Overall Production Cost

Savings in water, energy, chemicals, and processing time combine to significantly reduce the total cost of dyeing for manufacturers.Sustainable & Eco-Focused Operation

Reduced water and energy consumption support compliance with modern sustainability standards and environmental regulations.High Productivity & Consistent Results

Stable temperature control and optimized circulation ensure repeatable, high-quality dyeing outcomes across different fabric types.

© Arum Industries 2025. All rights reserved.

About us

Engineering Excellence for the Textile Dyeing Industry

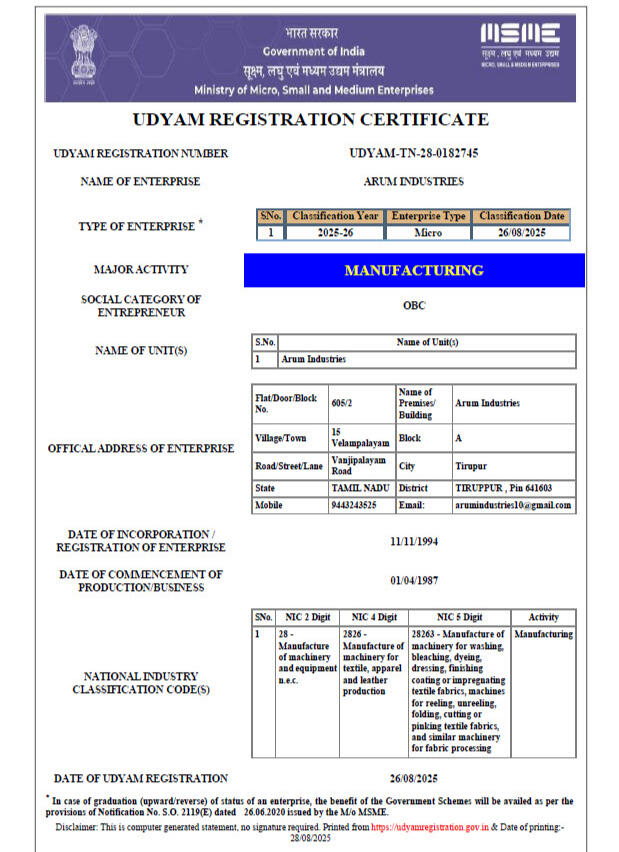

Since 1987, ARUM Industries has been a trusted partner in the design and manufacture of advanced textile dyeing machinery. Our comprehensive product portfolio includes HT/HP Softflow Dyeing Machines, Balloon Padding Machines, and Reversing Machines—all engineered to deliver precision, efficiency, and reliability.Renowned by textile manufacturers worldwide, our machines stand out for their durability, consistent performance, superior surface finish, and outstanding wear resistance. With decades of proven expertise and a commitment to continuous innovation, we provide solutions that empower our clients to achieve excellence in textile production.Driven by Expertise, Guided by Innovation

Our strength lies in our ability to anticipate and adapt to the evolving needs of the global textile industry. By closely monitoring market trends and customer requirements, we continuously enhance our product range to address diverse production challenges.Each machine is subjected to rigorous quality testing against strict parameters to ensure flawless performance. Beyond manufacturing, we are committed to our customers’ long-term success through comprehensive after-sales support and service.Our Team

At ARUM Industries, our greatest asset is our people. We are powered by a team of dedicated professionals who work collaboratively to deliver precision-engineered solutions with timeliness and care. Our workforce includes:- Engineers – driving design and innovation

- Technicians – ensuring flawless assembly and performance

- Quality Controllers – upholding the highest industry standards

- Sales & Marketing Executives – providing personalized customer supportWith a quality-first philosophy, every product that leaves our facility is tested to exceed industry benchmarks—ensuring our clients receive machinery they can trust for years to come.

© Arum Industries 2025. All rights reserved.

Contact

Head office:

ARUM Industries

SF No.605/2, Vanjipalayam road,

Kavilipalayam pudur pirivu,

Tirupur - 641603

India.Reach UsFill out the contact form below or connect with us directly through email at [email protected] or by mobile +91-8062179791. A member of our team will respond promptly to your inquiry.We look forward to assisting you and building lasting relationships with our valued customers worldwide.

© Arum Industries 2025. All rights reserved.

Thank you

Thank you contacting us. A member of our team will respond promptly to your inquiry.

© Arum Industries 2025. All rights reserved.